Jaguar Land Rover (JLR) said a cyber incident has severely disrupted its operations. The company reported that both production on factory lines and retail activity at dealers were affected. Systems were shut down as a precaution and are being brought back in a controlled manner, according to the company’s statements.

JLR stated there is no evidence at this stage that customer data has been stolen. This means the company has not found signs that personal details or payment information were accessed while the incident is being handled.

The automaker, a British luxury brand owned by Tata Motors, did not describe the technical method used in the attack and did not share information about the source of the intrusion. The immediate focus is on restoring applications safely and keeping services stable as checks continue

Operational effects were felt across the network. A UK plant on Merseyside told staff not to report for shifts after systems were taken offline, according to local and trade reports. These steps are part of common safety actions used to contain digital incidents and to prevent harmful code from spreading.

Insider revenge cyberattack freezes 1,000 workers — Eaton hit with massive disruption and losses

Before this cyber issue, the brand had already been managing earlier challenges reported in recent months, including changes to model timetables. The new disruption adds pressure to the company’s day-to-day operations while recovery work continues.

Impact on factories, dealers, and customers

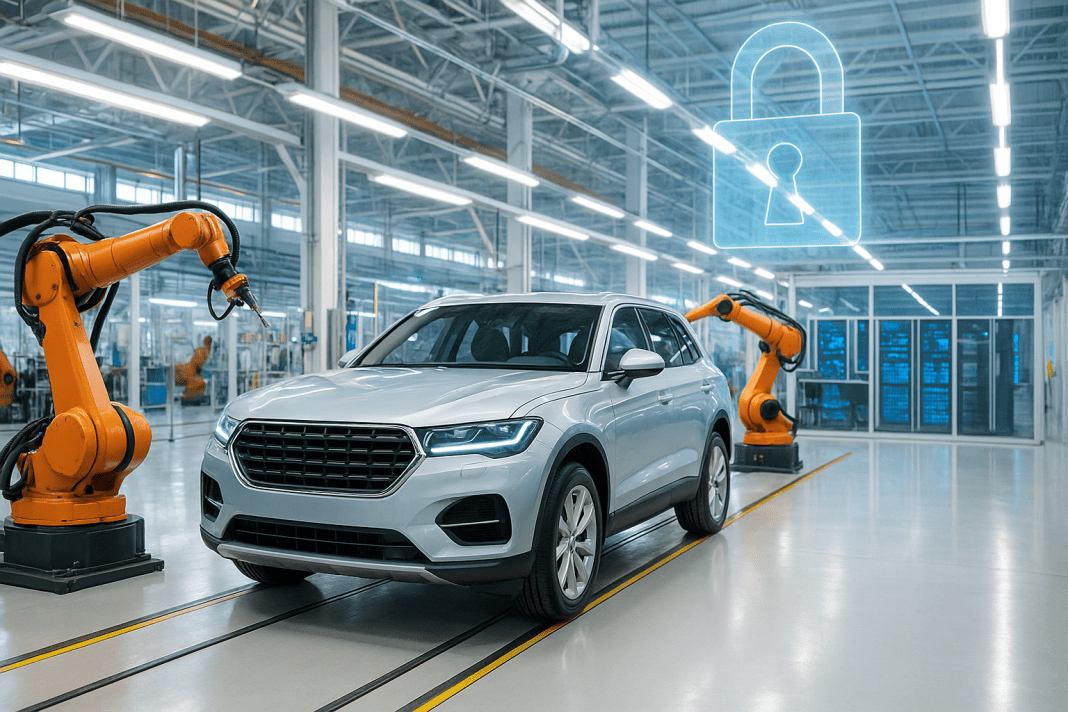

Modern car production depends on software that orders parts, schedules tasks, and runs quality checks. When those tools go offline, lines can pause quickly, even if just one component is delayed. That is why even a short shutdown can lead to stoppages or slower output until systems are confirmed safe and switched back on.

Retail and servicing also rely on connected tools. Dealer systems manage new vehicle registrations, workshop bookings, warranty approvals, and parts availability. If those services slow or pause, customers may face rearranged appointments, delayed handovers, or temporary alternatives at reception desks while digital tools are checked. Reports in the UK described interruptions to new-car registration processes around the time of the incident.

In incidents like this, companies often follow a staged plan:

-

Isolate affected networks to stop the spread.

-

Verify the status of backups and core applications.

-

Restore services one by one, watching for errors.

JLR said it is restarting global applications step by step. Bringing systems back gradually helps teams check data integrity and service stability at each stage. The company has not provided a public timetable but has confirmed that restoration work is underway.

Orange confirms ransomware breach with 4 GB of customer data exposed on dark web

Large manufacturers also coordinate with suppliers and logistics partners. Automotive supply chains use “just-in-time” delivery, where parts arrive at plants exactly when needed. If ordering portals or shipment trackers are paused, parts can be late, which can halt a station on the line. Dealers may also adjust collection slots or service times while central tools are being restored. These are expected effects when a company temporarily takes systems offline as a safety measure.

The company’s public updates have repeated three points:

-

Retail and production activities were severely disrupted.

-

Systems were shut down to mitigate impact and are being brought back carefully.

-

There is no evidence at this time of customer data being stolen.

Recent UK cyber incidents and sector backdrop

Several UK businesses have reported cyber incidents this year. A major national retailer resumed a key click-and-collect service in August after a 15-week suspension that followed a hack disclosed in April. That case showed how recovery can take time as companies check systems, rebuild services, and confirm security controls before returning to normal.

DaVita Under Siege: Cyberattack Hits Dialysis Giant, Put 2.7 Million Lives at Risk

Automotive companies face specific risks because production now relies on industrial controllers, robots, and connected planning tools. If those systems are interrupted, even briefly, output can slow or stop. Sales and after-sales are also digital, from online orders to workshop scheduling, so retail teams may switch to manual workarounds during outages.

In the current case, JLR has emphasized the protective shutdown, the controlled restart of applications, and the statement that customer data shows no signs of theft based on checks so far. The company’s communications have focused on operational status and service restoration rather than technical details of the intrusion.

Industry reports note that cyber incidents affecting large brands are part of a wider rise in attacks on industrial and commercial systems. These incidents can involve attempts to lock files, disrupt operations, or exfiltrate data. When factories and retail systems are involved, the effects can be visible to customers in the form of paused production, slower transactions, or rescheduled appointments while companies carry out checks.